“Walls are no longer just a backdrop, but are used as design elements in their own right. With ARCHIPANELS the possibilities for creative wall design are endless. The walls provide a new surface to enhance the space.”

WHY ARCHIPANELS?

1. Signature panels, designed by the best contemporary architects and designers, made with the highest percentage of recycled raw material possible.

2. High engineering and innovation in its finishing process.

3. Large formats and depth of relief, only possible to do with our technology, give us a surprising lightness and speed of assembly.

4. Flame retardant certification thanks to its innovative second layer technology.

5. Sustainability, through the conscious and proactive use of methods that take care of people and our planet, generating a positive impact on our environment.

HIGH TECHNOLOGY AND INNOVATION

Innovation in our finishing process allowing a high definition in the geometry of our panels. Our development engineering and the most advanced technological tools in our production system are the guarantee of the highest quality of our products.

The best architects and industrial designers of our team collaborate closely with our production units to increase the competitive capacity of our panels.

All the products in our collection are tested in our development department and technology center in Carcaixent.

ARCHIPANELS as observable, calibratable and improvable competition.

For this reason, we reflect innovation in all our processes AND we develop products in different structures using

technology investments and R&D opportunities.

Creativity + Sustainability + Innovation

RECYCLED AND RECYCLABLE

We manufacture with light foams with high breathability, low thermal conduction and high durability and inertness that does not rot and resists the capture of moisture.

All our materials are free of CFC's HCFC's and HFC's.

PU is aseptic, which ensures the non-existence of germs.

In most cases, Archipanels panels are fixed in such a way that they can be easily retrieved and separated, therefore they can be reused, albeit in less demanding applications.

How?

PU foam waste can be ground up and reprocessed into other panels, there is even the option of creating chemical recycling. The term chemical recycling describes the chemical conversion of polyurethanes to produce polyols for second-life applications. Three technologies have been developed: hydrolysis, aminolysis and glycolysis.

The main raw material of our panels is polyurethane and in order to optimize the impact on the carbon footprint, it contains recycled marine PET, the result of collaboration with the ECOALF Foundation.

Believers that the planet must be cared for for future generations, we have a firm commitment to increasing the percentage of recycled material year after year.

DESIGN

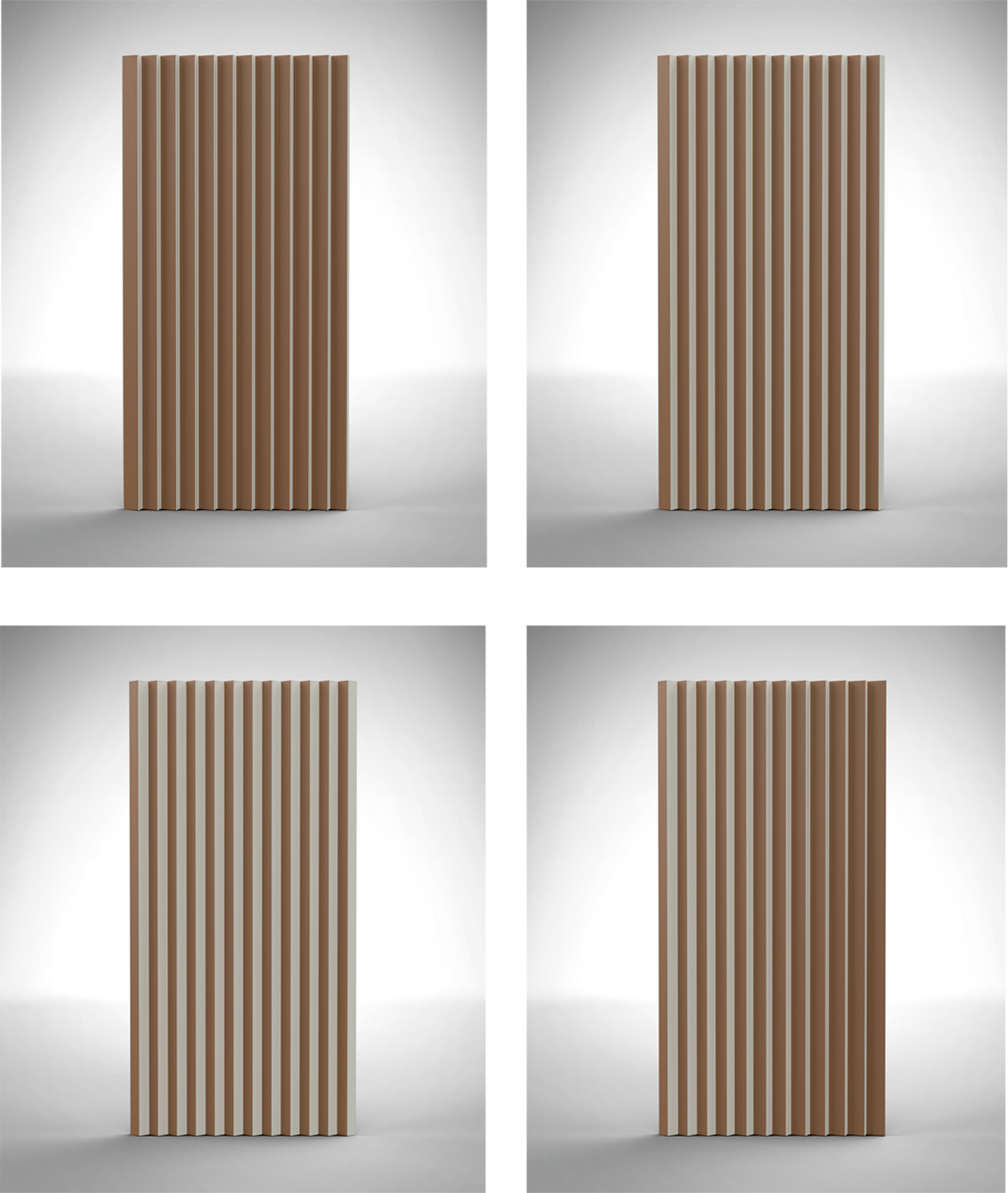

Design is perhaps the most differentiating point of ARCHIPANELS and the focus of the creative process, which is based on the active creation of products and processes, seeking inspiration in the most varied forms of vision in different cultures. At the same time, ARCHIPANELS approaches architectural concepts that range from the sober and conservative to the most contemporary and disruptive. Our designers flee from fashion and trends in search of architectural conclusions to achieve icons, designs that become contemporary classics.

LIGHTNESS AND QUICK ASSEMBLY

ARCHIPANELS stimulates creativity and inspires users to create spaces according to their style and personality.

ARCHIPANELS products do

made possible in a simple way thanks to its ease of installation and its versatility.

Panels of great lightness, versatile, easy to install and adaptable to any space.

With the aim of creating forward-thinking application systems and offering the most innovative solutions, ARCHIPANELS develops adaptable surface systems that aim to provide application flexibility.

LARGE FORMAT AND RELIEF WITH TIMELESS FINISHES

Geometric reliefs with unevenness of +/-40mm only possible thanks to our technology, this gives us surprising design freedom.

ARCHIPANELS enhances the intensity of the material and the complexity of the high technology with which it works, transforming the composition into an opportunity to create value in spaces.

We go beyond the limits of interior design and conventional architecture to explore unprecedented formats and volumes. Freed from the primary function of covering, ARCHIPANELS panels become original skins on which the creativity of designers and architects is exercised. With ARCHIPANELS, disruptive effects are created to achieve exciting reliefs and textures, transforming recycled material into sophisticated coatings such as a backdrop or a tapestry.

Where some see an invisible WALL,

ARCHIPANELS SEE AN OPPORTUNITY.

CEILINGS AND ACCESSORIES

Archipanels goes beyond the limits of interior design and conventional architecture to explore unprecedented formats and volumes.

All our panels are prepared to be placed on ceilings and can be machined to apply plugs and switches.

Geometric textures, finishes and elegant reliefs make up the Archipanels palette, which transforms recycled material into sophisticated coverings such as a backdrop or a tapestry.

Archipanels thus enhances the intensity of the material and the complexity of the highest technology with which it produces, transfiguring the composition into a unique and relevant space.

Our color palette has been carefully selected by our design team, offering all the colors in any of the collections in a transversal way so that they can be combined in the same space.

INTERNATIONAL REGULATIONS

At Archipanels we rigorously comply with international safety regulations by offering a resistant and guaranteed material verified in our technical data sheets and certificates for each of the collections.